BDNDT created to answer the demand of today’s “third party evaluations” concept, independent of owner and manufacturer, and to provide an accurate survey of equipment’s conditions. Every Day we try to add some uniqe inspection service for boiler in bangladesh. We provide better service in low cost for all. Our services include evaluation of Boiler, Pressure Vessel and Steam Pipe. We also offer Nondestructive and Technical Services.

Boiler NDT Test List

Phased Array Ultrasonic Testing (PAUT)

Visual Testing (VT)

Ultrasonic Testing (UT)

Ultrasonic Thickness Measurement Testing (UTG)

Magnetic Particle Testing (MT/MPI)

Liquid Penetrant Testing (PT/LPI)

Radiographic Testing (RT)

Positive Material Identification (PMI)

Boiler Hydraulic Pressure Test

Boiler Flue Gas Analyzers Test

Boiler Efficiency/Performance Testing

Endoscopy/Borescope Inspection

Hardness Inspection

Phased Array Ultrasonic Testing (PAUT)

BDNDT Provide Phased Array Ultrasonic Testing (PAUT) Inspection Service for Boiler in Bangladesh. Phased Array Ultrasonic Testing (PAUT), also known as phased array UT, is an advanced non-destructive inspection technique that uses a set of ultrasonic testing (UT) probes made up of numerous small elements. Each of these is pulsed individually with computer-calculated timing to create the phased aspect of the process, while the array refers to the multiple elements that make up a PAUT system.

Visual Testing (VT)

BDNDT Provide Visual Testing (VT) Inspection Service for Boiler in Bangladesh.Visual testing is an NDT method that involves the direct observation of a component to detect surface discontinuities. It is the simplest and most fundamental form of NDT, often serving as a preliminary step before applying more complex methods. VT can be performed with the naked eye or with the aid of optical instruments such as magnifying glasses, borescopes, and video scopes.

Ultrasonic Testing (UT)

BDNDT Provide Ultrasonic Testing (UT) Inspection Service for Boiler in Bangladesh. Ultrasonic Testing (UT) Uses high-frequency sound waves to detect internal flaws and measure material thickness. Widely used for measuring wall thickness (e.g., in tubes, headers, and piping) to detect wall thinning due to corrosion/erosion, and for detecting internal defects and cracks in welds. Advanced UT (phased array, TOFD, IRIS) offers more detailed analysis.

Ultrasonic Thickness Measurement Testing (UTG)

BDNDT Provide Ultrasonic Thickness Measurement Testing (UTG) Inspection Service for Boiler in Bangladesh. Ultrasonic thickness measurement (UTM) is a method of performing non-destructive measurement (gauging) of the local thickness of a solid element (typically made of metal, if using ultrasound testing for industrial purposes) based on the time taken by the ultrasound wave to return to the surface. This type of measurement is typically performed with an ultrasonic thickness gauge.

Magnetic Particle Testing (MT/MPI)

BDNDT Provide Magnetic Particle Testing (MT/MPI) Inspection Service for Boiler in Bangladesh. Magnetic particle testing is an NDT method used to detect surface and near-surface discontinuities in ferromagnetic materials. MT involves magnetizing a ferromagnetic material and then applying fine ferromagnetic particles to the surface. Discontinuities in the material, such as cracks or voids, disrupt the magnetic field, creating a leakage field. The ferromagnetic particles are attracted to these leakage fields, forming visible indications of the discontinuities.

Liquid Penetrant Testing (PT/LPI)

BDNDT Provide Liquid Penetrant Testing (PT/LPI) Inspection Service for Boiler in Bangladesh.Liquid Penetrant Testing (PT/LPI) Involves applying a colored or fluorescent dye to the surface to reveal surface-breaking defects in non-porous materials. Suitable for inspecting non-magnetic parts or where MT is not feasible, such as certain welds, tube plates, and de-superheater components.

Radiographic Testing (RT)

BDNDT Provide Radiographic Testing (RT) Inspection Service for Boiler in Bangladesh. Radiographic Testing (RT) Uses X-rays or gamma rays to create an image of the internal structure on a recording medium. Effective for detecting internal volumetric defects like porosity, slag, and inclusions in welds and castings.

Positive Material Identification (PMI)

BDNDT Provide Positive Material Identification (PMI) Inspection Service for Boiler in Bangladesh. Positive material identification (PMI) is the analysis of a material, this can be any material but is generally used for the analysis of metallic alloy to establish composition by reading the quantities by percentage of its constituent elements. Typical methods for PMI include X-ray fluorescence (XRF) and optical emission spectrometry (OES).

Boiler Hydraulic Pressure Test

BDNDT Provide Hydraulic Pressure Test Inspection Service for Boiler in Bangladesh. A boiler hydro test is a stress procedure used to determine the integrity of all aspects of a given boiler unit. The test involves filling the boiler with water and pressurizing to at least one and half times the maximum specified operating pressures for a short duration. During this test, if there are any defects in the boiler structure, the test will fail, and the boiler will not pass inspection for routine use.

Boiler Flue Gas Analyzers Test

BDNDT Provide Flue Gas Analyzers Inspection Service for Boiler in Bangladesh. A flue gas analysis measures the types and levels of gases appliances give off. They should be performed after installing any appliance that generates heat, filters or creates gas. By regularly testing flue gases, you can help customers fine-tune their heating appliances so fuel is used efficiently—saving energy and cutting down on their running costs. Plus, checking gas levels can literally be a lifesaver — catching dangerous levels of gases like carbon monoxide before they put anyone at risk.

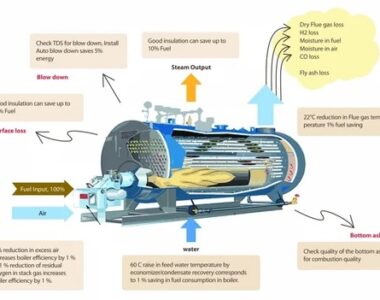

Boiler Efficiency/Performance Testing

BDNDT Provide Efficiency/Performance Testing Inspection Service for Boiler in Bangladesh. Boiler efficiency and performance testing primarily uses the Direct Method and Indirect Method to evaluate how effectively a boiler converts fuel energy into usable steam. The Direct Method (or input-output method) compares the energy output in the steam to the energy input from the fuel, providing a fast, overall efficiency percentage. The Indirect Method is more detailed, as it measures all the heat losses (such as from flue gas, radiation, and unburnt fuel) and calculates efficiency as 100% minus the total losses.

Endoscopy/Borescope Inspection

BDNDT Provide Endoscopy/Borescope Camera Inspection Service for Boiler in Bangladesh. A borescope is an inspection camera, which is inserted into an object to enable the operator to see the inside of the structure, engine, casting, or some other manufactured device. Borescopes are also used to explore environments to enable us to see areas we wouldn’t otherwise be able to view. Today, borescopes are often used remotely.

Hardness Inspection

BDNDT Provide Hardness Inspection Service for Boiler in Bangladesh. Hardness inspection in a boiler can refer to two things: testing the water hardness to prevent scale buildup or testing the mechanical hardness of the boiler’s metal tubes. For water hardness, chemical test kits or electronic analyzers are used to measure the concentration of calcium and magnesium ions, ensuring they remain below a certain threshold (typically less than 1 ppm) after treatment to prevent scaling. For the metal tubes, methods like the Brinell, Rockwell, or Vickers tests are used to verify mechanical properties like strength and quality, especially for high-pressure boilers.

With planned outage maintenance through Industrial Boiler & Mechanical, you can expect:

service tech crew scheduling

project management & client communication

equipment rental & purchase management

safety oversight

inspector coordination

service/maintenance reporting

system testing & restoration

contingency planning

Specifically, an annual boiler inspection addresses the labor, material, equipment and supervision to:

remove all safety relief valves, and replace them with valves provided by customer

open the boiler(s), inspect tubes, tube sheets, level controls

close the boiler(s), clean outside area and prepare for firing

perform calibration service and performance testing on the boiler safety interlocks, controls and valves

inspect related equipment including deaerators, feedwater systems, economizers, blowdown systems, etc. as applicable