We Know Non-destructive testing (NDT) is a testing and analysis technique used by industry to evaluate the properties of a material, component, structure, or system for characteristic differences or welding defects and discontinuities without causing damage to the original part. NDT is also known as non-destructive examination (NDE), non-destructive inspection (NDI), and non-destructive evaluation (NDE).

CIVIL NDT: Non-destructive tests (NDT) are test methods which are used to examine the hardened concrete structure for their suitability for its intended use without interfering in any way with the integrity of the material or its suitability for service.

Various non-destructive methods are commonly used of testing concrete have been developed to analyze properties of hardened concrete, which are given below.

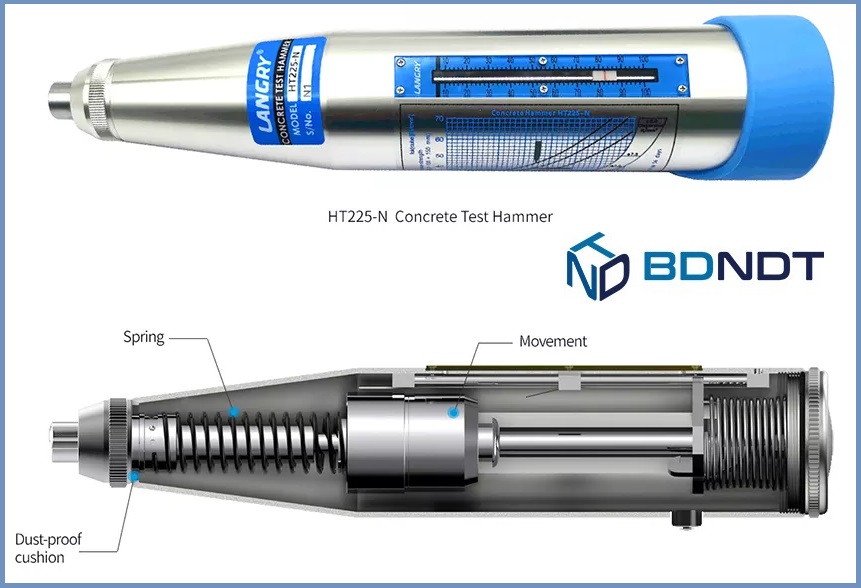

1. Rebound Hammer Test

The rebound hammer test measures the elastic rebound of concrete and is primarily used for estimation of concrete strength and for comparative investigation.

02. Ultrasonic Pulse Velocity Test

It is used for the finding the compressive strength of concrete.

3. Carbonation Depth Measurement Test

This NDT Method is used to determine the depth of concrete affected due to combined attack of atmospheric carbon dioxide and moisture causing a reduction in level of alkalinity of concrete, and reinforcement may suffer from corrosion as a result.

4. Radiographic Test

Radiographic test is used to detect voids in the concrete and the position of stressing ducts.

5. Permeability Test

Permeability test of concrete structure Method is utilized to find the permeability which is the measure of flow of water through the concrete.

6. Acoustic Emission Techniques

These Method have been used to study the initiation and growth of cracks in concrete.

7. Penetration Resistance or Windsor Probe Test

This test is used to measure the surface hardness and hence the strength of the surface and near surface layers of the concrete.

8. Half-cell Electrical Potential Method

This NDT test is used to detect the corrosion potential of reinforcing bars in concrete.

9. Covermeter Test

This test method is used to measure the cover to reinforcement bars in structure and also the diameter of reinforcement used in existing member.

10. Sonic Integrity Test method

Sonic integrity test is using an instrumented hammer providing both sonic echo and transmission methods. It is broadly used to test the quality of concrete structures.

11. Tomographic Modelling

Tomographic modelling, which uses the data from ultrasonic transmission tests in two or more directions, is employed to detect voids in concrete.

12. Impact Echo Test

It is used to detect location and extent of defects such as cracks, voids, delamination, honeycombing and debonding in plain, reinforced concrete and post-tensioned concrete structural members.

13. Ground Penetrating Radar

Ground Penetrating radar or impulse radar testing is used to detect the position of reinforcing bars or stressing ducts. This method is used in place of radiographic inspection for inspection of post-tension cables, conduits in concrete and osition of reinforcement bars.

14. Infrared Thermography

This method is used to detect concrete defects such as voids, cracks, delamination and other anomalies in concrete. This method is also used to detect water entry points in buildings.