BDNDT is One of the best NDT Inspection Company in Bangladesh. BDNDT Provide Surface Roughness Testing Services in All Over Bangladesh.

We Know Surface roughness is a critical aspect of many industrial processes, as it can significantly impact the performance, quality, and functionality of manufactured products. Surface roughness measurement can help to determine whether surfaces meet industry standards and safety requirements for performance, as well as help you track process variables that might influence surface characteristics such as aging, chemical deposition, or mechanical wear. If you are involved in material engineering research and development, production process control, or quality assurance testing, then this page on surface roughness measurement will provide you with detailed information about various techniques, benefits, and drawbacks of each, explain surface roughness parameters and discuss applications.

Instrument – That use for Inspection

Importance of Measuring Surface Roughness

BDNDT Help to find Surface Roughness on the job. The measurement of surface roughness is a key quality control process that can significantly impact the performance and lifespan of a product. For instance, in mechanical components, a high level of surface roughness can lead to increased friction, rapid wear, and premature failure. Conversely, a surface that is too smooth may not retain sufficient lubrication, leading to increased friction and wear. Researchers have shown that “lubricant load carrying capacity is largely affected by surface texture, roughness, and their interactions.”

Methods of Measuring Surface Roughness

- Contact Methods

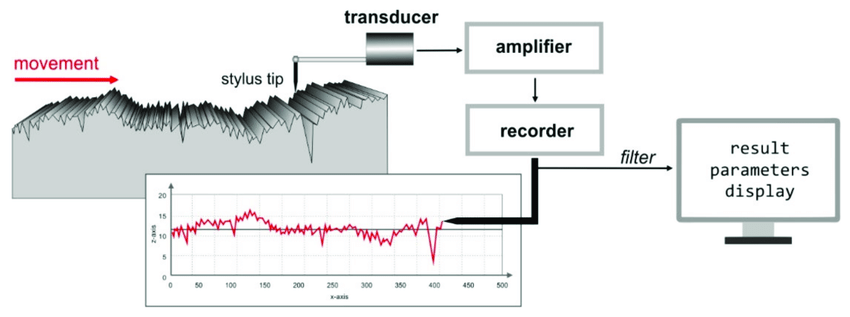

- Stylus Profilometry

- Non-Contact Methods

- Optical Profilometry

- Atomic Force Microscopy

- Surface Roughness Parameters

- Profile Parameters

- Areal Parameters