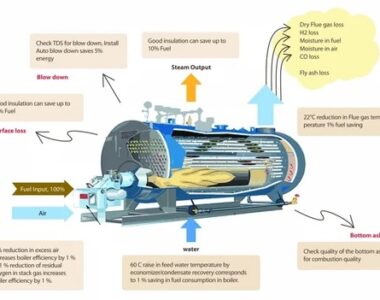

BDNDT Provide Boiler flue gas analysis test service in Bangladesh. We also provide flue gas analysis test service in Power plant and Others Industries. We know A boiler flue gas analysis test involves inserting a probe into the boiler’s flue to measure the levels of combustion gases like (O_{2}), (CO), and (CO_{2}) to check for efficiency and safety. The test is performed using a portable analyzer, and readings are taken at both the high and low settings of the boiler. Results are compared to manufacturer specifications to ensure optimal performance and to detect issues such as incomplete combustion or flue leaks.

What is Flue Gas Analysis?

A flue gas analysis measures in Boiler the types and levels of gases appliances give off. They should be performed after installing any appliance that generates heat, filters or creates gas. By regularly testing flue gases, you can help customers fine-tune their heating appliances so fuel is used efficiently—saving energy and cutting down on their running costs. Plus, checking gas levels can literally be a lifesaver — catching dangerous levels of gases like carbon monoxide before they put anyone at risk.In Bangladesh BDNDT Provide that service.

What is the purpose of a flue gas analysis?

Unless there’s a huge concentration of particularly smelling gas lingering around, it’s unlikely you or your customers would notice without accurate testing — until bigger problems occur. A flue gas analysis reveals problems, including blocked flues, incorrect air-to-fuel ratios, poor venting, safety risks, and expensive energy inefficiencies.

By analysing the levels of oxygen (O₂), carbon monoxide (CO), and carbon dioxide (CO₂), tradespeople can see how effectively a system burns fuel or if a blockage has occurred. If a boiler isn’t burning fuel efficiently, it may lead to higher energy bills, increased wear and tear on equipment, or dangerous carbon monoxide buildup. If something is blocked or jammed the flues, dangerous gases like carbon monoxide (CO) can back up into the customer’s home.

Why is Flue Gas Analyzing Test Required for Boilers?

-

- Combustion Efficiency Test

- Analyzing the flue gas shows how well the fuel is burning.

- Whether fuel is being wasted

- Whether the boiler is running at maximum efficiency

- This analysis reduces fuel consumption and saves operating costs.

-

- Ensuring safety

- If CO (Carbon Monoxide) is high in the flue gas, it is very dangerous.

- This test shows –

- Whether CO is leaking or not

- Whether incomplete combustion is taking place

- As a result, the risk of accidents is reduced.

-

- Boiler Health Test

- Flue gas shows:

- Whether the boiler tubes are clean or not

- Whether the air-fuel ratio in the furnace is correct or not

- Whether the boiler pressure/temperature is working properly

- These increase the boiler’s lifespan.

-

- Maintaining environmental standards (Emission Compliance)

- Nox, SO₂, CO₂, etc. are measured in the flue gas to see if the harmful emissions for the environment are within the limits.

- In many cases, this is also a legal obligation.

-

- Operation Optimization

- By testing the flue gas, you can better set the boiler:

- Reducing Excess Air

- Fixing the Draft

- Optimizing the Fuel/Air Ratio

- This improves the performance of the operation.

-

- Troubleshooting

- Abnormal values of the flue gas can be detected

- Burner problem

- Air leak

- Soot accumulation

- Incomplete combustion

- If these are known in advance, they can be repaired before they become major problems.

My Another Boiler NDT Test List

- Phased Array Ultrasonic Testing (PAUT)

- Visual Testing (VT)

- Ultrasonic Testing (UT)

- Ultrasonic Thickness Measurement Testing (UTG)

- Magnetic Particle Testing (MT/MPI)

- Liquid Penetrant Testing (PT/LPI)

- Radiographic Testing (RT)

- Positive Material Identification (PMI)

- Boiler Hydraulic Pressure Test

- Boiler Efficiency/Performance Testing

- Endoscopy/Borescope Inspection

- Hardness Inspection

Which Machine used for This Inspection:

- Simultaneous, individual measurement and display of all relevant measurement parameters by (O2, CO, CO2, flue gas and ambient temperature, CO environment, draught and pressure). Display configurable via the testo Smart App

- Simultaneous, additional measurements via the testo Smart App (e.g. gas flow pressure, flow and return temperature)

- Easy and intuitive menu guidance

- Digital documentation, data transfer and customer data management via testo Smart App

BDNDT Used Testo 310 II Flue Gas Analyser Standard Kit for Boiler flue gas analysis test.The Testo 310 II test procedure involves simple, one-button operation for flue gas analysis (O2, CO, temp) and specific steps for draft/pressure tests, requiring probe zeroing in fresh air before placement in the flue for running measurements, and using a plug for gas pressure tests, all guided by intuitive menus and connectable to a smartphone app for documentation and reporting.