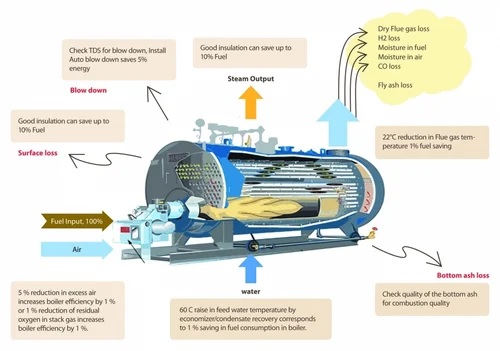

Boiler Efficiency & Performance Measurement Testing Price in Bangladesh. If you are looking a NDT company for Boiler Efficiency & Performance Measurement Testing Inspection Analysis for your company then please contact with us. We provide Testing, Inspection, Monitoring, Training, Consultancy, Verification, Research and Development services all over Bangladesh. Boiler efficiency and performance testing primarily uses the Direct Method and Indirect Method to evaluate how effectively a boiler converts fuel energy into usable steam. The Direct Method (or input-output method) compares the energy output in the steam to the energy input from the fuel, providing a fast, overall efficiency percentage. The Indirect Method is more detailed, as it measures all the heat losses (such as from flue gas, radiation, and unburnt fuel) and calculates efficiency as 100% minus the total losses.

Efficiency

Check out the efficiency of your old boiler with a simple stack analysis or preferably for a more accurate assessment, measure the gas input vs. steam or hot water output. The data will give you a general idea of the difference between the fuel cost of the existing boiler and a new unit. Based on the results of the stack evaluation, a more comprehensive evaluation of your boiler room requirements should be performed. Boiler size, load characteristics, turndown requirements, back-up requirements, fuel type, control requirements, and emission requirements, all should be evaluated. The result will be an accurate review of the potential savings in fuel, maintenance, and boiler room efficiency that can mean substantial cost improvement for your facility.

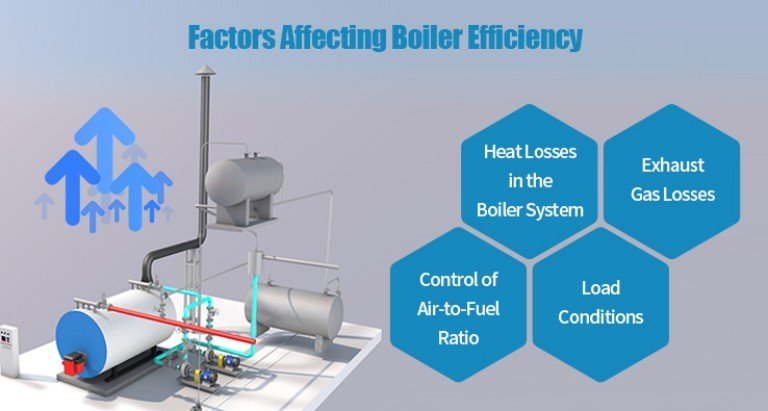

The following are the principal factors affecting efficiency calculations:

- Flue gas temperature

- Stack Losses

- Heating medium temperatures (steam pressures in the case of steam

boilers) - Radiation and convection losses

- Excess air

- Ambient air temperature

- Heating Medium Temperatures

- Turndown

- Fuel specification

- Steam quality (in the case of steam boilers)