BDNDT Provide Liquid Penetrant Testing (PT) or Dye Penetrant Testing (DPT) Service in Bangladesh. Basically boiler penetrant test (PT), also known as dye penetrant testing (DPT), is a non-destructive inspection method that uses a liquid dye to detect surface defects in a boiler.

Liquid Penetrant Testing (LPT), also referred to as penetrant testing (PT), liquid penetrant examination (LPE),dye penetrant testing (DPT), and dye penetrant testing (DP), is a nondestructive examination (NDE) method that utilizes fluorescent dye to reveal surface flaws on nonporous materials (metals, plastics, or ceramics) which might not otherwise be visible.

Step by Step Dye Penetrant Testing

Step 1 – Precleaning of the Surface

The 3 spray cans (aerosol) are provided for this test. First one is named cleaner. The technician sprays the cleaner to the test object and then cleans the surface with non-used rag or cloth. The sprayed material is evaporated rapidly. So the technsion needs to clean the surface instantly.

Step 2- Application of Penetrant

In the second step, the technician applies penetrant spray can to the surface which is in sharp red color. The technician needs to wait for 5 to 15 minutes depends on test procedure. In this time, the penetrant liquid enters to the crack (normally is not visible). The penetrant liquid soaks inside of the defects/ imperfections by capillary action.

Step 3- Removal of the Excess Penetrant Liquid

In the third step, the technician removes penetrant liquid from the surface by rag or cloth and uses back and forth rubbing to clean the surface. No red color should be visible after cleaning. Then technison takes a clean rag and sprays some cleaner on a cloth and then cleans the surface one more time. This can be done two or three times to remove all penetrant liquid from the surface. Please note by the capillary action; the penetrant liquid still is in the cracks or hot tear or any other imperfection. It will not come out by cleaning as described.

Step 4 – Application of Developer

In the fourth step, the technician takes the developer spray can and agitates it and then sprays to the surface. Then he waits for 10 minutes. In this time, the defect will be visible, the developer material uses reverse capillary action and bleeds out the red penetrant, and if there is a crack in the surface, you will see a red line within the white color covered by developer material.

Step 5 – Evaluation / Interpretation

In the fifth step, The ASNT Level II liquid penetrant inspector evaluates the test result based on the acceptance criteria indicated in the approved test procedure. Please note one indication might be considered imperfection and be rejected by one acceptance criteria and be accepted by another one. So it is imperative that the test be evaluated with right acceptance criteria.

Step 6 – Liquid Penetrant Test Report

The advantage that a liquid penetrant inspection (LPI) offers over an unaided visual inspection is that it makes defects easier to see for the inspector.

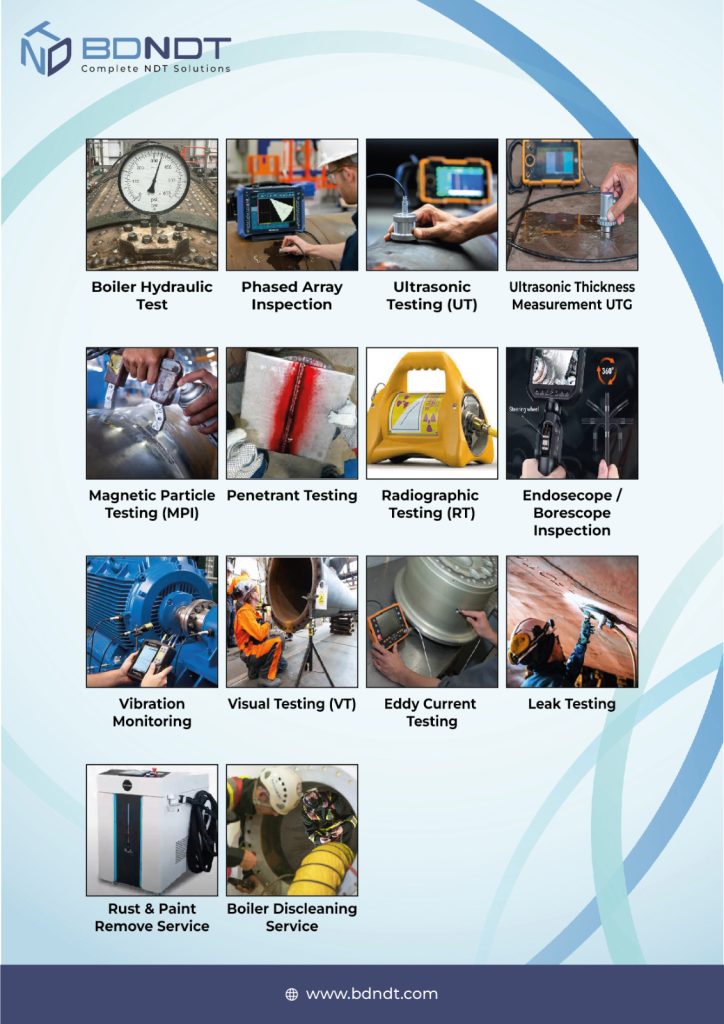

We Also Provide Boiler Others Service that below.