Concrete Coating Thickness Gauge Positector 200 in Bangladesh

৳ 355,000.00৳ 360,000.00 (-1%)

200C1 PosiTector® 200C Coating Thickness Gauge with Standard Display, Measures Coatings on Concrete, Fiberglass up to 150 mils / 3800 Microns – 6000-1 + PRB200C

3 Ranges Available in Standard or Advanced Versions

200B – 0.5 – 40 mils (13 – 1000 µm) paint on plastic, sheetrock, wood

200C – 2 – 150 mils (50 – 3800 µm) coatings on concrete, fiberglass

200D – 2 – 300 mils (50 – 7600 µm) polyurea on concrete and other thick coatings

The PosiTector® PT-200 measures coating thickness on drywall, concrete, wood, plastic and more using ultrasound technology. Advanced model can measure up to 3 individual layer thicknesses in a multi-layer system and features a graphic readout for detailed analysis of the coating system.

On-Screen Statistics – continually displays/updates average, standard deviation, min/max thickness and number of thickness readings.

Features

Includes NIST Traceable Calibration Certificate

USB port for fast, simple connection to a PC and to supply continuous power. USB cable included

Solvent, acid, oil, water and dust resistant – meets or exceeds IP5X

Thick impact-resistant Lexan display

Bi-color indicator light

2 Year Warranty

Shock-absorbing, protective rubber holster

Quality high-flex cable and strain relief

Comfortable ergonomic finger grip reduces operator fatigue

Plastic-tipped probe will not scratch surface

Probe Cable Length is 3 ft (1 meter)

Made in the USA

Frequently Asked Questions

Do your instruments require any formal training for use? Do you offer ‘demo’ models?

No. Our instruments are designed for simple operation, feature easy-to-use menus, both full and quick instruction manuals, and helpful videos. In lieu of demonstration models, we provide unlimited technical support via telephone and/or email, and a limited 30-day money back guarantee.

Is the PosiTector 200 calibrated at the factory?

The PosiTector 200 arrives fully calibrated and ready to measure. A Long-Form Certificate of Calibration traceable to NIST or PTB is included, which documents actual readings taken by your instrument at our calibration laboratory on standards traceable to a national metrology institute. Beware of ‘Certificates’ or ‘Certificates of Conformance’ offered by competitors. These typically do not include actual instrument readings, and are often insufficient to meet common quality requirements.

The PosiTector 200 is factory calibrated to measure most polymer coatings out of the box without calibration or adjustment. If required, a simple gage adjustment can be made to a coating sample of known thickness as close as possible in composition to the intended application. For best results, the thickness of the sample should be equal to or slightly greater than the maximum expected thickness of the coating to be measured.

DeFelsko’s Solution

The ultrasonic PosiTector 200 C (standard or advanced) gage is ideal for measuring most coating on concrete applications. With a coating thickness measurement range of 50 to 3800 µm (2 to 150 mils), this gage is recommended for customers desiring a single non-destructive measurement solution for most applications. The PosiTector 200 C requires little or no calibration adjustment for most applications. Figure 1 provides a cross-sectional view of a representative 125 to 375 µm (5 to 15 mil) coating on large aggregate concrete that is ideal for the PosiTector 200 C.

Figure 1: Coating on rough, large aggregate concrete

The ultrasonic PosiTector 200 B gage is ideal for measuring coating thickness from 13 to 1000 µm (.5 to 40 mils). While not specifically designed for measuring on concrete, after a simple calibration adjustment the ‘B’ probe may demonstrate improved repeatability when measuring hard, thin coatings over smooth surfaces. Figure 2 represents an application where the PosiTector 200 B may be preferred.

Figure 2: Thin coating on smooth, cement surface

If the concrete surface is smooth but uneven, or rough and porous, one would expect the measurement values to vary accordingly. When examined under magnification, locations where the coating has flowed into pores or crevices may appear as outliers when measurements are taken. For example in Figure 3, the bump in the substrate at “A” results in a significantly different thickness than nearby point “B”. It is up to the user to compare results to the specification or expected thickness when analyzing results. Some results may need to be omitted when making calculations.

Figure 3: Thick soft coating on concrete

For an application such as Figure 4, that has both a rough substrate and a rough coating surface, it may be necessary to take several readings within individual small areas, calculate average readings, and then compare these values. These averages can then be compared against the specification. Destructive testing on the sample shown in Figure 4 identified a 1 to 3 mm (40 to 115 mil) variation within a ¼” diameter area.

Figure 4: Coating on rough lightweight concrete

How to Measure

Ultrasonic testing measurement works by sending an ultrasonic vibration into a coating using a probe (i.e. a transducer) with the assistance of a couplant applied to the surface. A 4 oz bottle of a common water-based glycol gel is included with every instrument. Alternatively, a drop of water can serve as couplant on smooth, horizontal surfaces.

Figure 5: Taking a measurement

After the drop of couplant has been applied to the surface of the coated part, the probe is placed flat on the surface. Pressing down initiates a measurement (see Fig. 5). Lifting the probe when a double beep is heard holds the last measurement on the LCD. A second reading may be taken at the same spot by continuing to hold the probe down on the surface. When finished, wipe the probe and the surface clean with a tissue or soft cloth.

Graphics Mode (PosiTector 200 Advanced Models Only)

The right hand side of the PosiTector 200‘s screen can be used to display a graphical representation of the ultrasonic pulse as it passes through the coating system. This powerful tool enables the user to better understand what the gage “sees” below the surface of the coating.

Figures 6 & 7:

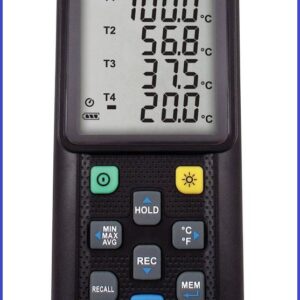

Left: PosiTector 200 C3 with Graphics Mode ON

Right: PosiTector 200 C3 with Memory Mode ON

The PosiTector 200

DeFelsko’s PosiTector 200 coating thickness gage is ideal for coating thickness measurement over a variety of non-metal substrates.

Two models are ideal for masonry coatings:

- The PosiTector 200 C1 is the economical and most common solution for measuring the TOTAL coating system thickness.

- The PosiTector 200 C3 is capable of measuring both TOTAL coating thickness AND up to 3 individual layer thicknesses in a multi-layer system. It also features a graphic readout for detailed analysis of the coating system.

Each PosiTector 200 comes complete with probe, protective rubber holster with belt clip, couplant, 3 AAA batteries, instructions, nylon carrying case with shoulder strap, Certificate of Calibration traceable to NIST, two (2) year warranty.

Size: 146 x 64 x 31 mm (5.75″ x 2.5″ x 1.2″) Weight: 165 G (5.8 oz.) without batteries

Conforms to ASTM D6132 and ISO 2808

Download Data Sheet Now

(All information collect from defelsko own website)

Reviews

There are no reviews yet.